Description:

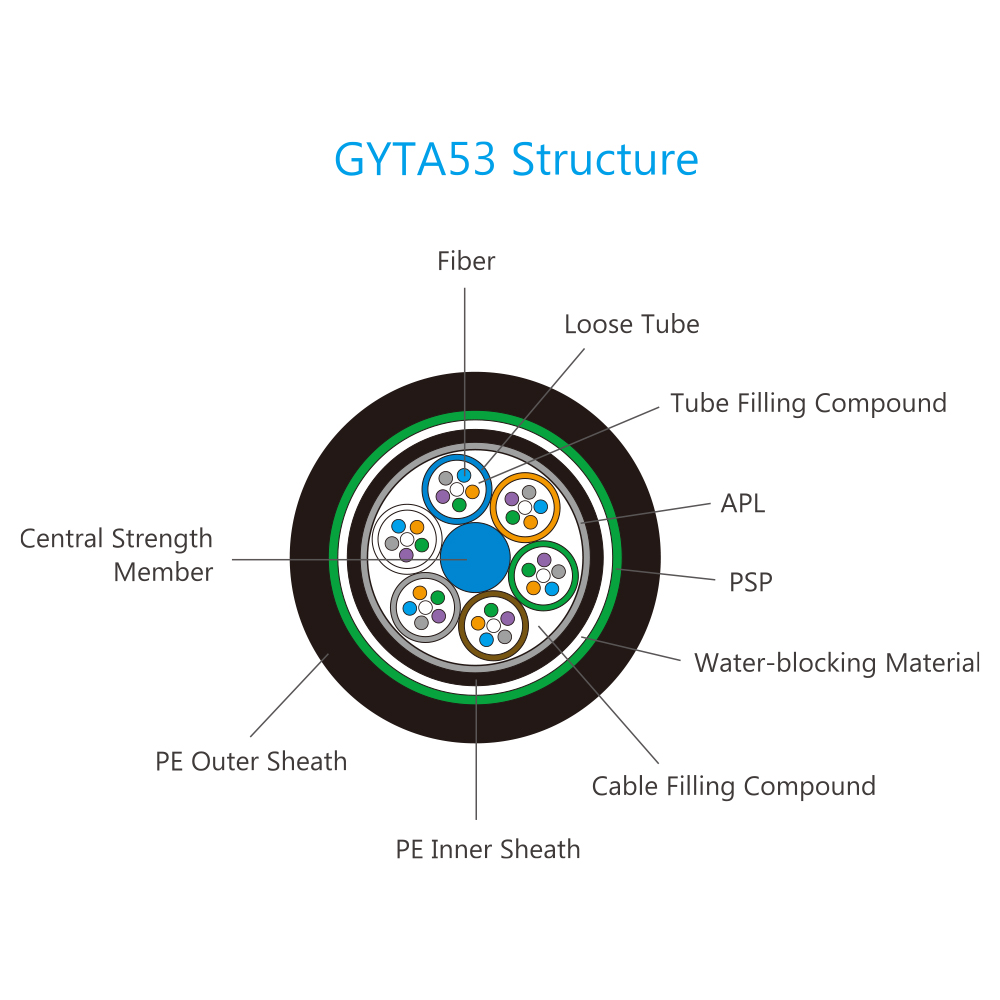

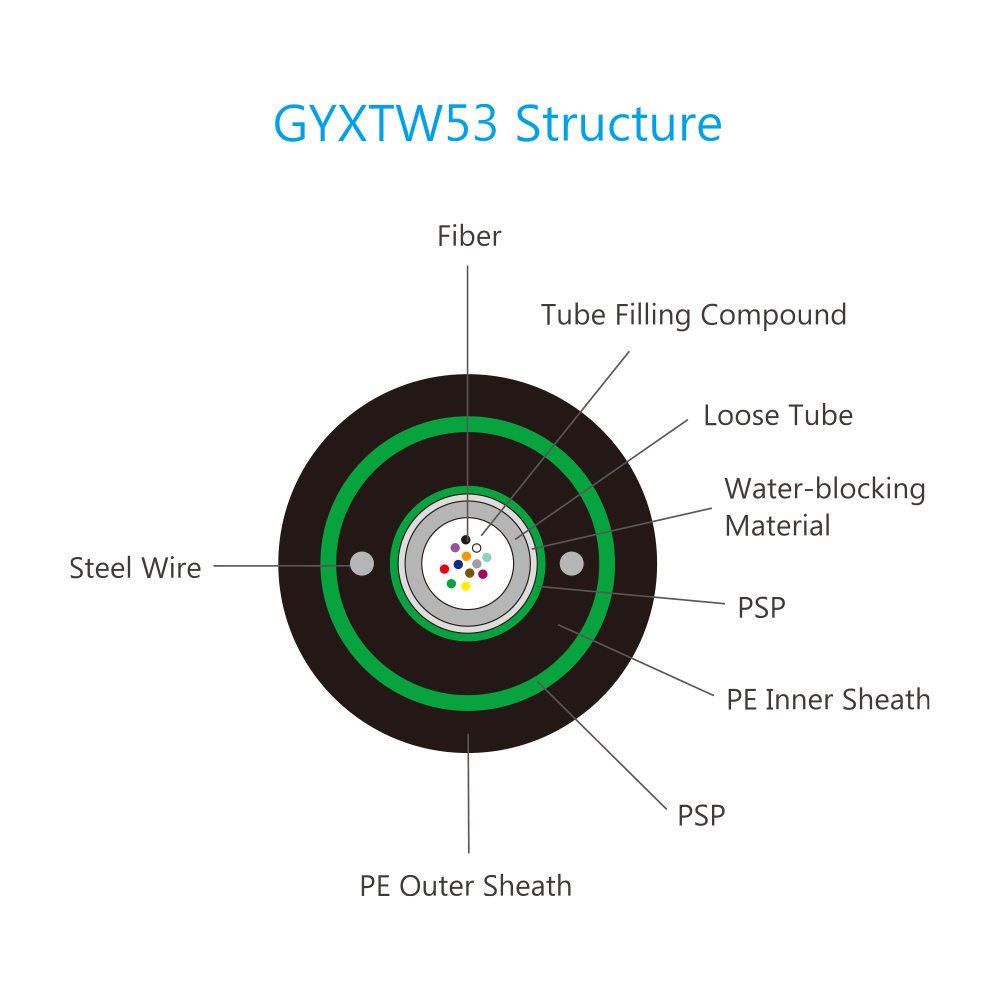

The fibers,250um,are positioned in a loose tube made of a high modulusplastic. The tubes are filled with a water-resistant filling compound.A steel wire,sometimes sheathed with polyethylene (PE) for cable with high fiber count,locates in the center of core as a metallic strength member.Tubes (and fillers) are stranded around the strength member into a compact and circular cable core.An Aluminum Polyethylene Laminate(APL) is applied around the cable core, witch isfilled with the filling compound to protect it from water ingress.Then, the cablecore is covered with a thin PE inner sheath.After the PSP is longitudinally appliedover the inner sheath, the cable is completed with a PE outer sheath.

Characteristics:

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube filling compound ensure a criticalprotection of fiber

Crush resistance and flexibility

The following measures are taken to ensure

the cable watertight:

Steel wire used as the central strength member

Loose tube filling compound

100% cable core filling

PSP enhancing moisture-proof

Water-blocking material

Application: duct/aerial/direct buride

Standards:

INGO GYTA53 cable complies with standard YD/T901-2001 as well as IEC60794-1

Technical Parameters:

| Cable Type (Increased by 2 fibers) | Fiber Count | Tubes | Filters | Cable Diameter (mm) | Cable Weight (kg/km) | Tensile Strength Long/Short term (N) | Crush Resistance Long/Short term (N/100mm) | Bending Radius Static/Dynamic (mm) |

|---|---|---|---|---|---|---|---|---|

| GYTA53 | 4 | 1 | 4 | 12.5 | 130 | 1000/3000 | 1000/3000 | 10D/20D |

Storage/Operating Temperature:-40℃ to +70℃

English

English

中文

中文 Português

Português